| Purpose Our mission is to “make first sample is final sample”. | |

| Scope of responsibility | |

| Abbreviation; PP- Pre-Production HR -Human Resources TOD -Time of Delivery BOM | |

| Required functional assistant from other departments; Activity Responsible Sample request program merchandiser | |

| Tools and equipments required; 1.Pen and pencil 2.Eraser and sharpener. 3.Calculator, files, ring files. 4.Computer, printer and scanner with internet, paper. 5.Pattern board, pattern cutter,scissor. 6.Fabric, trims and accessories. 7.Sewing machines, thread rewind machine, iron table. 8.GSM cutter & scale. 9.Dummy. | |

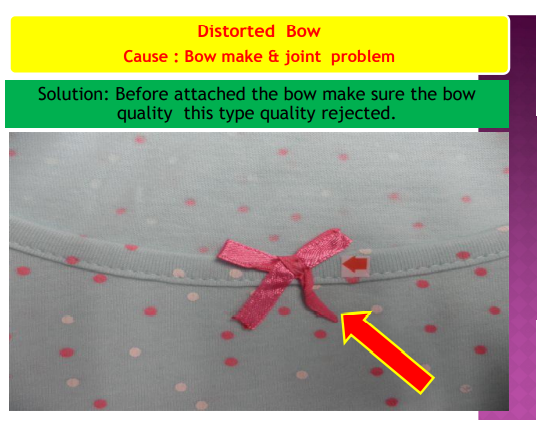

| Process Responsible position 1. At first we receive sample request / program from merchandiser. 2. Check style pack/design sketch if any critical issue than communication to buyer. 3. Style sketch check and briefing the pattern master than pattern making. 4. Fabrics check and confirm as per buyer requirement. 5. Sample making follow up and briefing the supervisor + sample man as per buyer requirement. 5. Production pattern check, confirm and delivery to cad and bulk cutting section. 6. Always discuss with buying house to any technical issue. 7. If create any technical or quality problem to given solution. 8. Check the sample quality according to buyer standard. 9. To monitor and supervise the daily work subordinates. 10. Received sample program from AGM/Deputy manager. 11. Sent to sample request hard copy to pattern master. 12. Follow up sample plan to meet lead time. 13. Follow up sample fabrics receive, cutting, sample making, finishing and send to buyer. 13. To keep any sample documents and report. 14. To communicate and coordinate to other concern department. 15. Pattern master make the pattern as per buyer style sheet/BOM sheet. 16. If buyer given the pattern by mail, pattern master collects the buyer pattern from cad than make the pattern with seam allowance. 17. If any confusion and pattern making problem to communicated the technical manager. 18. Pattern master completed the pattern sent to cutting section. 19. When sample approved pattern master check the pattern with follow last approval comments and sent to production. 20. Cutting in charge receive sample program, pattern, fabrics and cutting instruction to cutter man as per planning. 21. Cutter man following sample program as fabrication, quality, gsm, quantity and sample cutting. 22. After cutting if need print/emb. 23. Sent to cutting panel print and emb. Section. 24. If required garment treatment fabrics sent to washing dept. and after wash than cutting. 25. All cutting part send to sewing section. 26. Sample supervisor receive sample cutting parts, print/embroidery, and planning for sewing. 27. Collect the Q.C sheet/BOM/Technical sheet when getting input sample cutting parts. 28. Follow the comments before garment sewing and brief the sample man to make the sample. 29. Check the trims and collect from merchandiser/accessories store. 30. If found any sample making problem to concern sample manager and solution. 31. Time to time follow up sample check with buyer requirement while the making. 32. Ensure that completed sample is ok as per buyer required. Complete sample send to finishing/washing (if needed). 33. Sample man making the sample as per buyer instruction, quality,following measurement and complete the sample on timeAt first receive complete sample and do the ironing. 34. Sample QC checks the styling with Q.C sheet/BOM/Technical sheet. Check the all trims, fabrication, gsm, color and print/emb.Check the sample shape as per pattern, stitch tension, measurement report, sample pull test (if require) and keep all document. 35. If found any problem concern to sample manager and solve it. All are ok than sample poly man attached the sample tag on garment and delivery to merchandiser. |

STANDARD OPERATING PROCEDURE Sample Department